Circular Economy Models

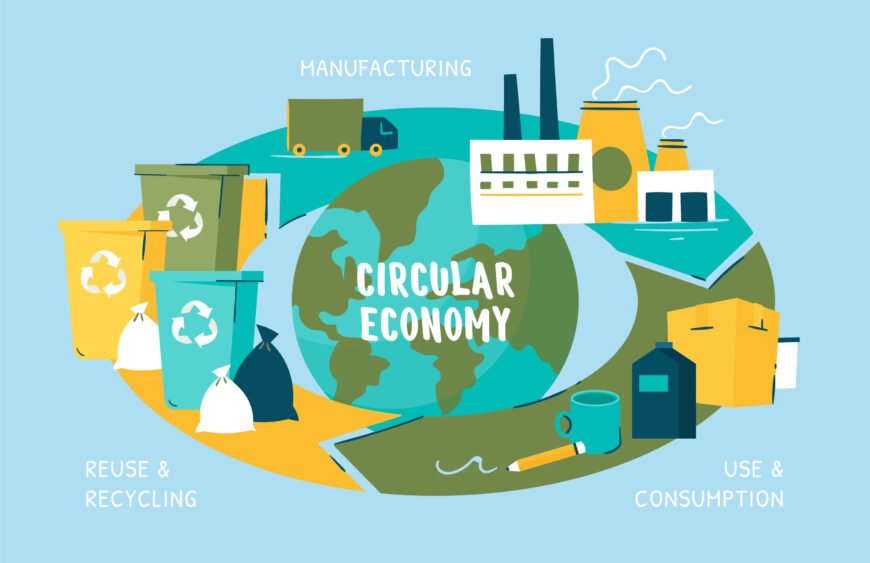

Circular economy models represent a transformative approach to traditional linear economic systems, aiming to minimize waste and make the most of available resources. Unlike the linear model, which follows a “take-make-dispose” pattern, circular economy models emphasize sustainability by designing products and systems that promote the continuous reuse, repair, and recycling of materials. The core principles of a circular economy include extending the lifecycle of products, using renewable resources, and creating closed-loop systems where waste from one process becomes input for another.

This model reduces the need for raw materials, minimizes environmental impact, and fosters innovation in product design and business practices. By focusing on durability, modularity, and resource efficiency, circular economy models encourage businesses to rethink how they create value and engage with consumers. This approach not only addresses pressing environmental issues but also offers economic opportunities, such as new business models and revenue streams, by shifting towards services like product-as-a-service or take-back schemes.

What steps can businesses take to shift from a linear to a circular economy model ?

Transitioning from a linear to a circular economy model involves several strategic steps. Businesses should begin by assessing their current processes and identifying areas where waste can be reduced or materials can be reused. This involves redesigning products and processes to enhance durability, modularity, and recyclability. Developing new business models, such as product-as-a-service or take-back schemes, can help create closed-loop systems where products are returned, refurbished, or recycled rather than discarded. Investing in technologies for efficient recycling and resource recovery is crucial, as is collaborating with suppliers and partners to create a circular supply chain.

Companies must also engage in consumer education to promote sustainable practices and foster a culture of circularity. Finally, setting measurable sustainability goals and tracking progress through key performance indicators (KPIs) helps ensure that the transition is effective and aligns with the company’s overall business strategy. By adopting these steps, businesses can successfully shift towards a circular economy, contributing to environmental sustainability and long-term economic resilience.

How does adopting a circular economy model impact a business’s financial performance ?

Adopting a circular economy model can have significant financial implications for businesses, both positive and challenging. On the positive side, circular models can lead to cost savings through more efficient use of resources, reduced waste disposal costs, and decreased dependency on raw materials. For example, implementing recycling and reuse practices can lower material costs and improve profit margins. Additionally, new business models like product-as-a-service can generate recurring revenue streams and enhance customer loyalty. However, the transition involves initial investments in redesigning products, developing new technologies, and establishing reverse logistics systems.

There may also be costs associated with educating consumers and training employees. Despite these upfront expenses, the long-term financial benefits often outweigh the costs, as businesses can achieve greater operational efficiency, tap into new markets, and mitigate risks associated with resource scarcity and regulatory pressures. Overall, while there are financial challenges, the potential for cost savings, revenue generation, and enhanced brand value make the circular economy model a financially viable and strategic choice for many businesses.

In what ways does a circular economy model impact supply chain management ?

A circular economy model significantly impacts supply chain management by emphasizing sustainability, resource efficiency, and closed-loop systems. Traditional supply chains are often linear, with a focus on efficiency and cost reduction. In contrast, circular supply chains prioritize the continuous flow of materials, minimizing waste and maximizing resource recovery. This shift requires changes in supplier relationships, as companies need to source materials that are recyclable or biodegradable and collaborate with partners who support circular practices. Logistics and reverse logistics become more complex, as businesses must manage the return, refurbishment, and recycling of products.

Supply chain transparency and traceability are crucial for ensuring that materials are properly tracked and processed. Additionally, circular supply chains often involve redesigning products to be easily disassembled and recycled, which can influence procurement and manufacturing processes. By adopting a circular economy model, businesses can create more resilient and sustainable supply chains, reducing their environmental impact and enhancing long-term efficiency.

How important are consumers in the success of circular economy models ?

Consumers play a critical role in the success of circular economy models by driving demand for sustainable products and practices. Their preferences and behaviors influence how businesses design, produce, and market circular products and services. Educated and engaged consumers can support circular economy initiatives by choosing products that are designed for durability, repairability, and recyclability. Participation in take-back programs, product rentals, and recycling schemes also contributes to the effectiveness of circular models. Businesses that effectively communicate the benefits of circular economy practices and educate consumers about sustainability are more likely to gain their support and foster loyalty. Additionally, consumer feedback can help businesses refine their circular economy strategies and address challenges. By aligning their values with circular principles and actively participating in circular practices, consumers help drive the adoption and success of circular economy models, creating a positive feedback loop that benefits both businesses and the environment.

What metrics and indicators can companies use to evaluate the success of their circular economy initiatives ?

Companies can measure the success of their circular economy initiatives using a variety of metrics and indicators that assess environmental, economic, and operational performance. Key metrics include material efficiency, which measures the proportion of materials that are recycled or reused compared to total input; waste reduction, which tracks the decrease in waste generated and disposed of; and resource recovery rates, which evaluate the effectiveness of recycling and recovery processes. Economic indicators such as cost savings from reduced material use, revenue from product-as-a-service models, and return on investment (ROI) from circular initiatives provide insights into financial performance. Operational metrics, including the percentage of products designed for disassembly and recyclability, and the efficiency of reverse logistics systems, reflect the effectiveness of circular processes. Additionally, customer satisfaction and engagement levels can indicate the success of circular product offerings and services.

Can you provide examples of successful circular economy models across different industries ?

Several industries have successfully implemented circular economy models, demonstrating the versatility and effectiveness of this approach. In the fashion industry, companies like Patagonia and Stella McCartney focus on using recycled materials and promoting product repair and recycling programs. Patagonia’s Worn Wear program encourages customers to buy used clothing and trade in old items for repairs or discounts. In the electronics sector, companies such as Dell and Apple have developed take-back programs and designed products for easier recycling and refurbishment. Dell’s “Closed Loop” program uses recycled plastics from old electronics to create new products.

The automotive industry also embraces circularity, with companies like Renault and BMW implementing vehicle recycling and remanufacturing processes. Renault’s “Renault Ecosystem” focuses on dismantling and reusing parts from end-of-life vehicles. In the construction sector, firms like Buro Happold and Interface are designing modular buildings and flooring products that can be easily disassembled and reused. These examples illustrate how circular economy models can be successfully applied across various industries, leading to resource efficiency, reduced waste, and innovative business practices.

Add a Comment